When beginning a bathroom or kitchen renovation, you have many decisions to make. Besides settling on a color scheme, design features and layout, you need to find the exact products you want for your home or property. You want sturdy cabinetry and storage solutions that look good and stand the test of time.

If you’re new to wood furnishings and fixtures, read through this guide to determine which wood is the best quality and how to spot the signs of superior woodwork.

Solid Wood vs. Veneer vs. Laminate Furniture

Understanding the differences between solid wood, veneer and laminate furniture can help you make the best choice for your home. Below, learn more about the differences between each type of furniture:

Solid Wood

Solid wood furniture is made from natural wood or plywood. It may be constructed with other materials, such as metal legs or screws. When it comes to furniture and fixtures, solid wood is the longest-lasting, best quality of wood. Unfortunately, solid wood construction is hard to find these days because it’s costly and very time-consuming to make products from. It’s much more common to find engineered wood furniture with a real wood veneer.

Solid wood is an excellent material for all types of furniture, including shelves and cabinetry. It won’t warp as easily as engineered wood. It’s also more affordable to repair than wood veneers because solid wood can be refinished repeatedly.

Wood is generally categorized as either softwood or hardwood. While many trees work as a source of solid wood, we at WG Wood Products make all of our products from solid pine and use solid maple for our doors. These are some benefits of solid wood furniture:

- Sustainability

- Durable construction

- Natural grain that’s easy to refinish

- Long life span

- Luxurious appearance

Despite the numerous benefits, solid wood also has some drawbacks to consider. Solid wood furniture can have higher upfront costs and be prone to damage, such as staining and chipping. Real wood furniture can also be heavier, which needs to be considered in case you decide to rearrange your furniture or move.

Veneer

Wood veneer furniture is made from a thin layer of hardwood combined with materials such as fiberboard and plywood. You can use wood veneer to achieve the look of solid wood without paying the same price. However, wood veneer furniture requires more effort than laminate, so it has a higher price point when compared to laminate furniture. Despite this, there are some notable benefits of veneer furniture. Wood veneer furniture offers:

- A cost-effective way to achieve a real wood appearance.

- Simplified maintenance.

- A higher resistance to warping.

- Unique designs and finishes.

Wood veneer has many pros, but there are also some cons. For example, wood veneer can be more delicate than other types of wood since it has a thin layer of natural wood on top, making it prone to scratches or chips. Wood veneer can also be more susceptible to water damage if water gets in between the layers.

Laminate

Laminate is composed of a composite base and plastic. There are two main types of laminate: high-pressure and low-pressure. High-pressure laminate has multiple layers, while low-pressure laminate is made from a single layer and a base.

Laminate is popular among homeowners for furniture since it can withstand heavy use and is easier to maintain compared to real wood or wood veneer. Some of the other benefits of laminate include:

- Cost-effectiveness.

- Modern appearances and finishes.

- Heat, scratch and stain resistance.

Laminate is manufactured, so you won’t be able to achieve the same wood grains or natural looks of real wood. It also lacks the strength of real wood. If you’re looking for a real wood appearance with the most benefits, you should choose solid wood. Solid wood furniture offers the most benefits for homeowners, including durability and a natural aesthetic.

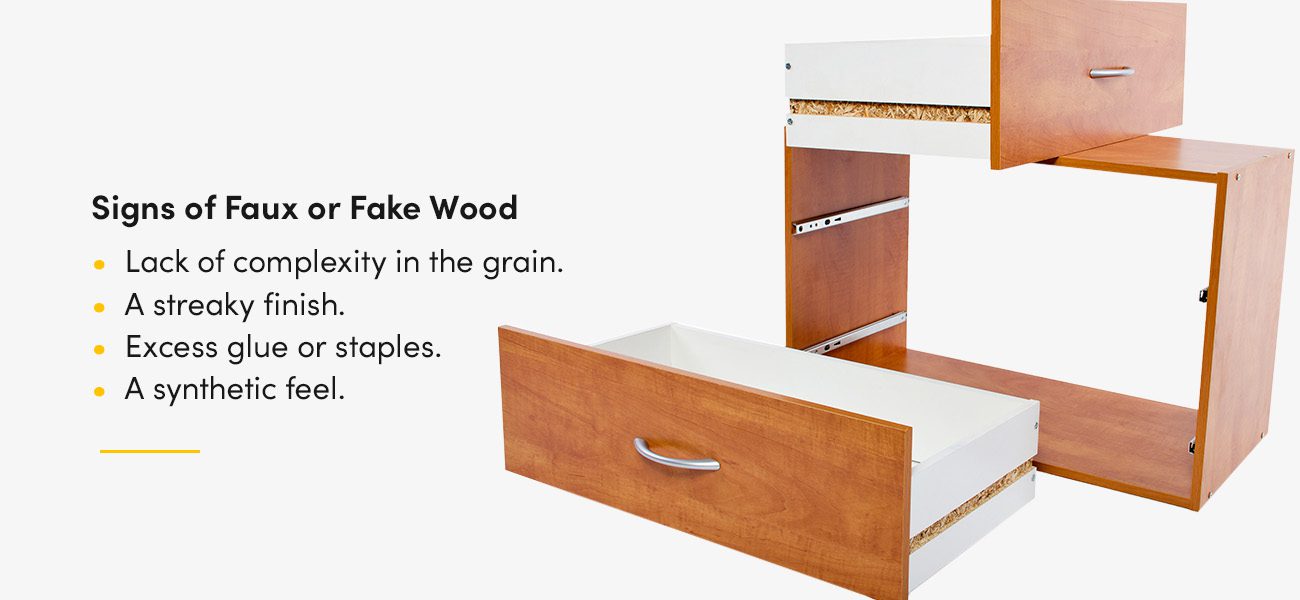

Signs of Faux or Fake Wood

When shopping for furniture, you’ll likely come across pieces that look like natural wood but are actually fake. However, it can be challenging to spot the signs if you’re not familiar with the signs of fake wood. Some of the signs to look for include:

- Lack of complexity in the grain.

- A streaky finish.

- Excess glue or staples.

- A synthetic feel.

Fake wood will also become more obvious when you closely inspect the furniture. For example, if you pull out drawers or look underneath furniture, you can see what the material is made from. The material may not look vibrant, or it may look more obviously plastic. You could also spot composite materials found in wood veneers and laminate products.

Signs of Real Wood Furniture

Real wood furniture has distinct benefits and will look better and last longer in your home. Knowing how to spot real wood furniture ensures you’ll choose the right pieces for your home. Some of the signs of real wood include:

- Weight: Solid wood is heavier than wood veneer or laminate since the entire construction is made from wood. If a piece of furniture seems lightweight, it’s likely fake wood. Instead, you should look for sturdy, heavy furniture if you want real wood.

- Grain patterns: Natural wood grain patterns are varied and distinct. If a piece looks like the grain is repeating or doesn’t have a lot of texture, it’s likely fake. Natural wood will always have distinct grain.

- Construction elements: Artificial wood won’t have the same construction elements as real wood, which can include dovetail methods for drawers, unfinished wood at the bottom and no grain on the edges.

- Price: Solid wood has a higher price point than fake wood, so a real wood furniture piece will usually be more expensive. Despite the higher price point, real wood has many benefits and will last longer in your home.

- Details: Ornate details can be carved into real wood but can’t be done with wood veneer or laminate. If you’re looking at a piece with carved ornate details, you’re likely looking at real wood.

Benefits of High-Quality Wood Products

Now that you know how to check wood quality and evaluate construction, you might wonder what difference quality makes. Solid wood and well-crafted construction and design have many advantages, such as:

- Character and charm: You can’t replicate the beauty of natural wood grains in plastic or laminate surfaces. Real wood gives off a pleasant, warm appearance. It also provides a timeless look and a solid feeling you can’t get with low-quality engineered wood.

- Customizability: Real wood, instead of wood veneer, can be carved into many shapes and patterns. It can also be stained and finished to match many interiors and aesthetics. Since even solid wood is easy to manipulate, it offers the most design flexibility. Ordering a plastic cabinet or shelf in a custom size might require the manufacturer to change its molds or tooling. Meanwhile, wood can be cut and shaped into many different sizes and designs. When you work with WG Wood Products, most of our customizations come at no extra charge!

- Durability: Solid wood and quality construction add years to a product’s useful life. It resists warping, cracks, scratches and dents. Also, solid wood can be re-sanded and refinished many times, giving it an even longer life span. Wood veneer generally can’t be sanded or refinished because the wood layer is extremely thin.

Invest in Quality Wood Medicine Cabinets From WG Wood Products

WG Wood Products is your go-to source for quality, solid wood recessed cabinets, shelving and other storage solutions. We make everything from spice racks to recessed toilet paper holders from solid wood right here in the United States. We offer the widest selection of recessed cabinetry, and if we don’t have what you’re looking for, we’ll build something custom.

Shop our collection of wood cabinetry and storage solutions for bathrooms and kitchens. If you find something you like or want to request custom sizing and finishes, complete our quote request form to discuss your project. Have questions, or want to experience our excellent customer service for yourself? You can always send us a message online and even include pictures of your room for advice.